Direct manufacturing costs such as labor and overhead can be directly traced to a single product. PepsiCo, Inc., produces more than 500 products under several different brand names, including Frito-Lay, Pepsi-Cola, Gatorade, Tropicana, and Quaker. Net sales for 2010 totaled $57,800,000,000, resulting in operating profits of $6,300,000,000.

Part of cost of goods sold

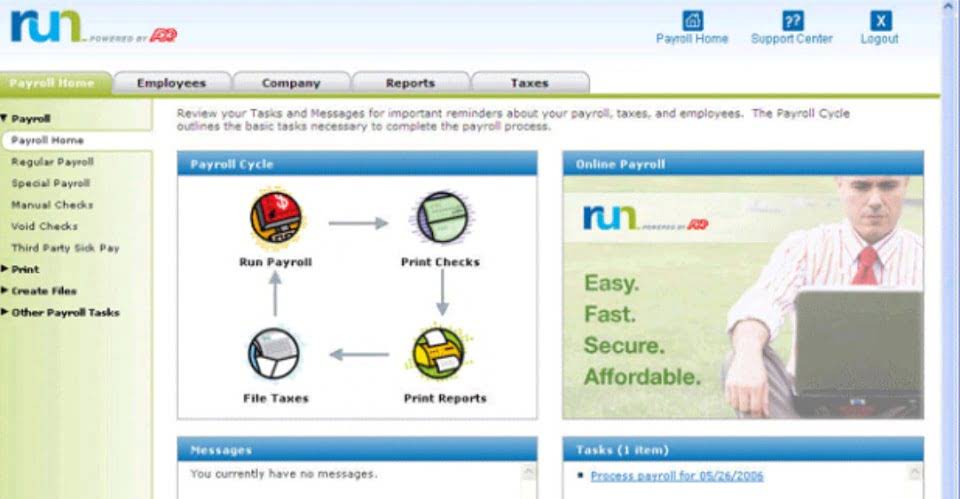

Therefore, always consult with accounting and tax professionals for assistance with your specific circumstances. This account is a non-operating or “other” expense for the cost of borrowed money or other credit. Modern MRP systems are designed in a manner that they flexibly support and integrate into any manufacturing business process, creating a complete business management platform for your company. However, you must remember to keep track of everything and run the actual total costs against the predicted costs. You should then assess if they are aligning at the end of the set time period or not and decide the necessary course of action to maintain or rectify the situation.

Costs on Financial Statements

Direct labor – cost of labor expended directly upon the materials to transform them into finished goods. Direct labor refers to salaries and wages of employees who work to convert the raw materials to finished goods. However, while you are looking for cheaper materials to help you drive down your costs, it is important that you ensure the quality and integrity of your products do not suffer because of it. This will ensure that you are increasing your profitability without losing your brand image and, consequently, customers. One of the areas where businesses spend a significant amount of their money is on materials.

Financial Reporting vs. Individual Products and Customers

Now, add the value of existing inventory to the cost of purchasing new inventory to calculate the cost of direct materials. Start by making a list of all the direct materials that are used to make the specific product and obtain the cost information for the direct materials you have identified. To calculate the cost of direct materials you need to know the cost of inventory. There may be options available to producers if the cost of production exceeds a product’s sale price. The first thing they may consider doing is lowering their production costs.

There are many reasons why this is happening, and it is essential to understand the factors contributing to the increase in manufacturing costs. It also includes administrative expenses like office supplies/paper clips/staplers/etc. Note “Business in Action 2.3.1” details the materials, labor, and manufacturing overhead at a company that has been producing boats since 1968.

- Direct labor manufacturing costs is determined by calculating the cost of employees directly responsible for producing the product.

- Once you know this total, you will be able to predict your total costs for a whole day, weeks, and even months of production.

- “When a manufacturer begins the production process, the costs incurred to create the products are initially recorded as assets in the form of WIP inventory.

- In addition to profitability, your pricing decisions can also impact your other strategic objectives like market share and customer satisfaction.

Indirect costs would include overhead such as rent and utility expenses. Total product costs can be determined by adding together the total direct materials and labor costs as well as the total manufacturing overhead costs. To determine the product cost per unit of product, divide this sum by the number of units manufactured in the period covered by those costs. We use the term nonmanufacturing overhead costs or nonmanufacturing costs to mean the Selling, General & Administrative (SG&A) expenses and Interest Expense. Under generally accepted accounting principles (GAAP), these expenses are not product costs.

Nonmanufacturing Overhead (Explanation Part

Your efficiency, productivity, as well as profitability will thus be maximized through this. One of the ways of doing this is to tool your manufacturing plant with more automated machines. Additionally, automated machines tend to be more efficient than human inputs, which in turn, will make your process faster and more productive as well. It will also give you all the necessary information and insights to reduce your costs and improve your profit margin. In addition to profitability, your pricing decisions can also impact your other strategic objectives like market share and customer satisfaction.

There are many reasons why manufacturing cost is essential, but one of the most important is that it helps you understand how much it costs to manufacture your product. In today’s manufacturing environment, when orders are filled in hours and days rather than weeks and months, it is critical for any enterprise to stay on top of these costs at all times. For over twenty-five years their time-tested technology has been giving businesses the edge over their competition. Product costs are treated as inventory (an asset) on the balance sheet and do not appear on the income statement as costs of goods sold until the product is sold. Manufacturing costs are also known as factory costs or production costs.

- Now let us consider what is likely to be consumed during its production.

- As a result, there is now a greater demand for human capital that can operate machines and oversee their operation.

- Direct costs for manufacturing an automobile, for example, would be materials like plastic and metal, as well as workers’ salaries.

- SMe Software’s complete Manufacturing Management Software is highly configurable, completely integrated business software for the small to mid-size manufacturer.

- Since nonmanufacturing overhead costs are outside of the manufacturing function, these nonmanufacturing costs are immediately expensed in the accounting period in which they are incurred.

- Direct labor costs include the wages and benefits paid to employees directly involved in the production process of goods or products.

What are direct manufacturing costs?

The consulting firm was also able to re-negotiate the manufacturing company’s contracts with poor-performing suppliers. The most significant disadvantage of non-manufacturing costs include ABC is that it can take a lot of time and effort to set up. You must set up the infrastructure for all your employees, which will take time and cost money.